Bearings belong among the key mechanical components that ensure efficient and reliable motion of rotary and linear parts in a variety of industrial applications. Without them, many machines and equipment would not function efficiently. In this article, we take a detailed look at the function, principle, and use of these parts.

Bearings are mechanical elements designed to reduce friction between moving machine parts. Their main purpose is to transmit load and ensure smooth operation of rotary or linear movements.

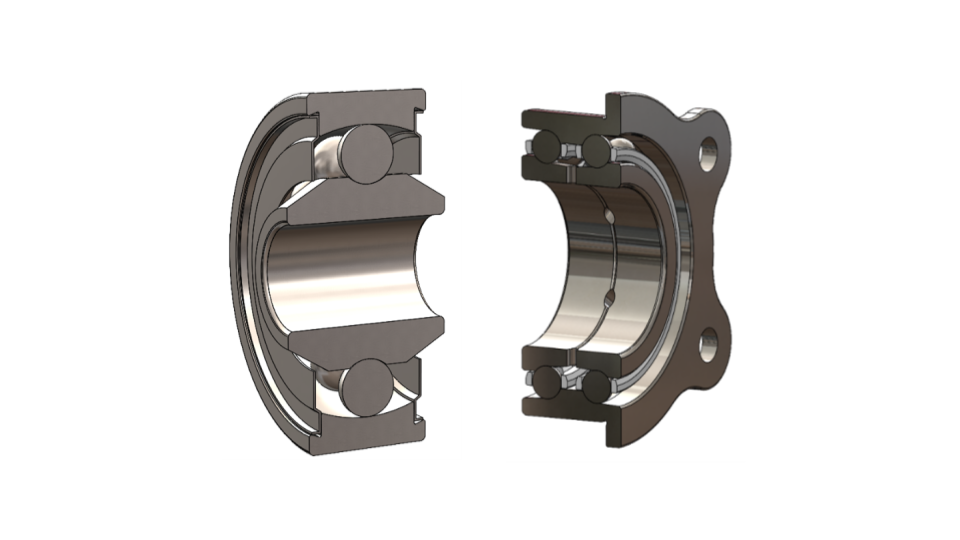

From a structural point of view, bearings consist of an inner and outer ring, rolling elements (balls, rolls or needles) and a cage ensuring uniform distribution of the elements.

Their main functions include:

These components work on the principle of rolling or sliding motion. Rolling bearings use balls or rolls to minimize contact friction, resulting in less wear and higher efficiency. On the other hand, sliding bearings create a lubricating layer between the moving surfaces, which ensures smooth motion and reduces wear.

They are essential in many industries:

In the aviation industry, these components have to withstand extreme conditions such as high temperatures, intense vibrations and enormous loads. For this reason, they are manufactured using high-strength materials such as ceramics or special alloys that ensure their long service life and corrosion resistance.

Bearings are critical to the reliability of the aviation industry, where they are used in engines, turbines, landing gear, as well as aircraft control systems. Their precise construction and high resistance to dynamic loads ensure flawless operation under extreme conditions.

Bearings are a key component of mechanisms, ensuring efficient transmission of forces, minimising friction and increasing equipment service life. Their importance is essential in various industrial and transport sectors.

If you are looking for quality components or expert consultancy, you will find reliable solutions for your applications at AKE Skalica.

The Avalon Australian International Airshow is one of the southern hemisphere's most prestigious civil aerospace, defence and space technology events. This biennial trade fair attracts more than 250,000 visitors from all over the world, including key industry players.

AKE Skalica will present itself at the Avalon Airport near Geelong, Victoria, in the Slovak stand under the auspices of The General Consulate of the Slovak Republic in Sydney and The Ministry of Foreign and European Affairs of the Slovak Republic.

This event is not only an opportunity for AKE Skalica, but also for Slovakia to demonstrate their technological innovations in aviation and establish new international collaborations.

Visitors to the Avalon Australian International Airshow 2025 will be able on 25 - 28 March to discover AKE bearings adapted to aeronautical applications and discuss future trends in avionics. AKE Skalica will present in Avalon its latest bearing designs intended for jet engines reflecting the growing demands for technological advancement and component durability in the aerospace industry.

With all the key players from the domestic and international aerospace and defence sectors under one roof, Avalon is the ideal opportunity for face-to-face interaction.

Thanks to a strong commitment from the Royal Australian Air Force and a significant Asian, European and US industry presence, Avalon provides a link between the Australian, regional and international aerospace industry at every level, ranging from Defence Force customers to major suppliers.

AKE Skalica's participation in the Avalon Airshow 2025 is an important step for the presentation of Slovak innovations on the global stage.

The basic and most widely used materials for the manufacture of bearing components used in aerospace applications include bearing steels 52100, HSS M50, HSS M50Nil. The trend nowadays is a gradual transition to the production of aerospace bearings exclusively from HSS M50 and HSS M50Nil steel. AKE Skalica has aerospace bearings included in its production programme, which are manufactured from all of these steels. We follow this trend and actively copy it when designing construction solutions for our new projects. It could be said that currently the production of HSS M50 and HSS M50Nil materials accounts for up to 80% of the total production of our production plant.

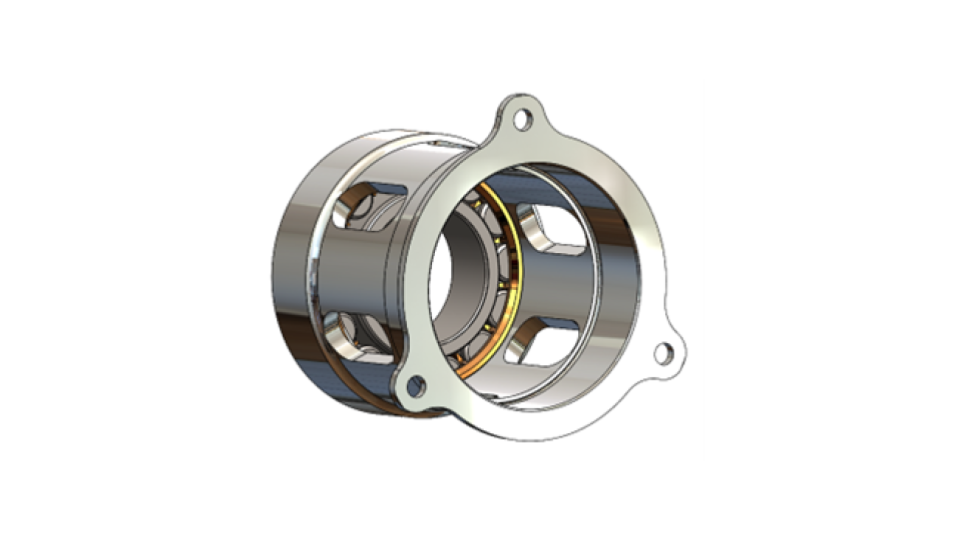

The bearings made of HSS M50Nil in combination with ceramic rolling elements are a special theme. (Si3N4 – Silicon Nitride). This design of bearings is called hybrid. The combination of these materials in the bearing design is ideal for use in high speed rocket engines, whether with solid or liquid fuel, due to its low coefficient of friction. We currently have both hybrid ball bearings and hybrid roller bearings in production.

The current trend in materials for the production of cages is polyamide blanks. One of the top materials is Ketron PEEK 1000 (Polyetheretherketone natural black), which can be used in environments with increased radiation, high temperature and chemical impacts due to its properties. Bearings with cages made of Ketron PEEK 1000 are therefore used in the aerospace manufacturing industry as well as in the nuclear power industry.

For the development, design and production of its products, AKE Skalica uses all of these materials. It is expected that in the future the number of types of AKE bearings, where these trendy materials will be used in various combinations, will increase. All of the trendy materials are suitable for the aerospace manufacturing industry, but they are also significantly more demanding in terms of processing and adherence to strict parameters. For this reason, we have implemented new state-of-the-art technology centres in our technological infrastructure. The combination of current material trends is used today in the manufacture of all design groups of aerospace bearings, in particular:

We consider bearings made of the above mentioned materials to be "best bearings".

Our company, a long-standing manufacturer in the aerospace manufacturing industry, continues to expand its product portfolio to provide innovative solutions for both civil and military aviation. As a top bearing manufacturer, we focus on developing and manufacturing bearings that meet the most demanding standards of aviation and aerospace component manufacturing. With an emphasis on new technologies and materials, we are constantly improving our offering, which includes a wide range of aerospace parts manufacturing.

Our product portfolio has been expanded to include several new types of AKE bearings, which are key ones to improving the performance and reliability of aerospace systems. Our latest products include engine bearings designed for high performance engines. These engine main bearings and other bearing types such as ball bearings, deep groove ball bearings, radial ball bearings, cylindrical roller bearings and hybrid bearings provide optimum stability and minimize wear under extreme conditions, which is essential for aerospace applications.

Our new prototype series of aerospace bearings focuses on improving efficiency and safety. In aviation and aerospace component manufacturing, for example, lightweight alloys and composite materials reduce the weight of aircraft and increase their fuel efficiency. Manufactured using the latest aerospace manufacturing technologies, these products enable better performance, lower operating costs and lower CO2 emissions.

Our military aerospace division, which holds a license to trade in defence industry products, offers a wide range of advanced solutions. These include the latest engine bearings for combat aircraft, drones and helicopters that are designed to withstand extreme temperatures and pressures. This authorization allows us to supply highly specialized AKE bearings that ensure maximum reliability in critical military operations. Our new radial ball bearings, cylindrical roller bearings and hybrid bearings increase manoeuvrability and extend machine life, contributing significantly to the safety and efficiency of aircraft operations.

As part of our global cooperation with international aviation and aerospace component manufacturing companies, we provide comprehensive tailor-made solutions. AKE bearings, including the latest deep groove ball bearings, radial ball bearings, cylindrical roller bearings and hybrid bearings are implemented in projects around the world where they meet stringent safety and quality requirements.

Our company, which holds a trading license for defence industry products, is constantly developing and contributing to the development of the aerospace manufacturing industry through new products and innovations. Whether they are engine main bearings or gearbox bearings, our goal is to deliver solutions that are not only reliable, but also technologically advanced. AKE aerospace bearings are designed to meet the needs of the aerospace industry and support its growth in the coming decades.

The aerospace manufacturing industry is also subject to trends. Their task is to take the functioning of bearings to an even higher level. Which of the manufacturing trends of the aerospace industry are applied in the AKE Skalica plant?

In the past year, we focused our development and production mainly on ball and roller bearings with an outer diameter up to 150 mm. All these bearings are designed and manufactured from HSS M50 material, which is currently one of the manufacturing trends in the aerospace industry.

Our next design development is a design solution for the production of bearings made of HSS M50Nil in combination with Ketron Peek 1000.

Manufacturing trends in the aerospace industry also relate to the way in which surface treatments are applied to improve the properties and, in particular, to extend the lifetime of bearings. They are implemented into the design solutions when designing customized bearings, which we call "customer design".

Customer design connects us with the customer's design teams and together we form one development team. One example of such cooperation with a customer is our joint design of the cooling of the working environment with a defined medium, in order to eliminate as much as possible the temperature changes to which the bearing is exposed in operation. This achieves an increase in bearing efficiency to the maximum level.

Current manufacturing trends in the aerospace industry also include simulation of the real operating conditions as accurately as possible in the bearing in the fit. In our external conditions, we are concerned with the adjustment of the forces that will act on the bearing in the bearing fit in real operation. At the same time, by setting these forces, we can ensure that the demanding bearing parameters that are designed in the drawing documentation are adhered to.

All these individual small parts of the development process allow us, in cooperation with the client's development team, to set the parameters of the developed bearing so that it works as efficiently and reliably as possible in the bearing fit for which it is designed.

Another major ongoing challenge that we are currently addressing is the development of bearings for a powerful jet engine with a thrust of 10,000 lbf.

Recently, there has been an increase in the need for new products and applications in the aerospace industry. In addition to the global leaders in aerospace OEMs creating a global need for bearings in the market, new projects and new players are entering the market to feed the increased demand for aerospace parts manufacturing.

This change has a direct impact on the increased need for key parts, including high-precision bearings.

The aerospace manufacturing industry is a segment of the supply and consumption of products and services with the highest level of safety, irrespective of whether they are intended for civil or defence use. Aerospace manufacturing uses the most modern and precise technologies and input materials for the actual production of parts. Being a manufacturer of Aerospace bearings requires a high level of experience and technological expertise.

In some cases the production of Aerospace parts involves a time commitment of several months. However, there were also situations when, due to the design and quality specifics of the product itself, the production of prototypes took more than 2 years. The most frequent request from clients nowadays is to start the production of a prototype delivery as soon as possible. The high demands on bearing quality must always be 100% met.

AKE Skalica is working intensively on the development of "production planning" to create sufficient spare production capacity in order to ensure flexibility in delivery times. It is our strength in the Aerospace manufacturing industry and at the same time our biggest challenge.

At AKE Skalica we have therefore taken all necessary steps to be able to offer the advantages we bring to the market as a medium-sized enterprise to our customers in the long term. We have set process standards so that instead of 18 months, we are able to deliver a prototype within 12 months at the latest from the conclusion of the technical documentation with the client.

Based on our own experience with B2B or B2C and the new clients we have acquired, we find that our strategic location in this area meets with a high level of interest from our clients. We are delighted to be able to contribute to their success and joint competitiveness in this way.

Today, the management of AKE Skalica is facing perhaps the biggest challenge in the plant's history. What is waiting for us?

We want to bring high quality and safe products, flexibility in customer communication and more flexible delivery times to the global market in the long term compared to our competitors. However, the ever-increasing demand for aircrafts products intended for civil or defence purposes is motivating us to rethink our medium-term plans.

We have therefore decided to significantly increase our investment in technological innovations for 2024/2025, while at the same time to strengthen staff at all levels of the company's management. These measures are expected to have the additional effect of increasing capacity 2-3 times progressively in the second half of 2024 and in 2025.

Just for the record, in 2024, with new customers, we put 67 new aircrafts prototype products into production for 2024/2025, which is 150% more than in 2023. Of these, 15 types were put into production this year for delivery by the end of 2024.

The challenge lies not only in the financial requirements, but mainly in the personnel area of recruiting, training and stabilising new staff and at the same time improving the working conditions of our tribal staff, which form the solid foundations of AKE Skalica bearing plant.

Copyright©2024 IMET-AKE | Privacy Policy | Terms and Conditions | Cookies