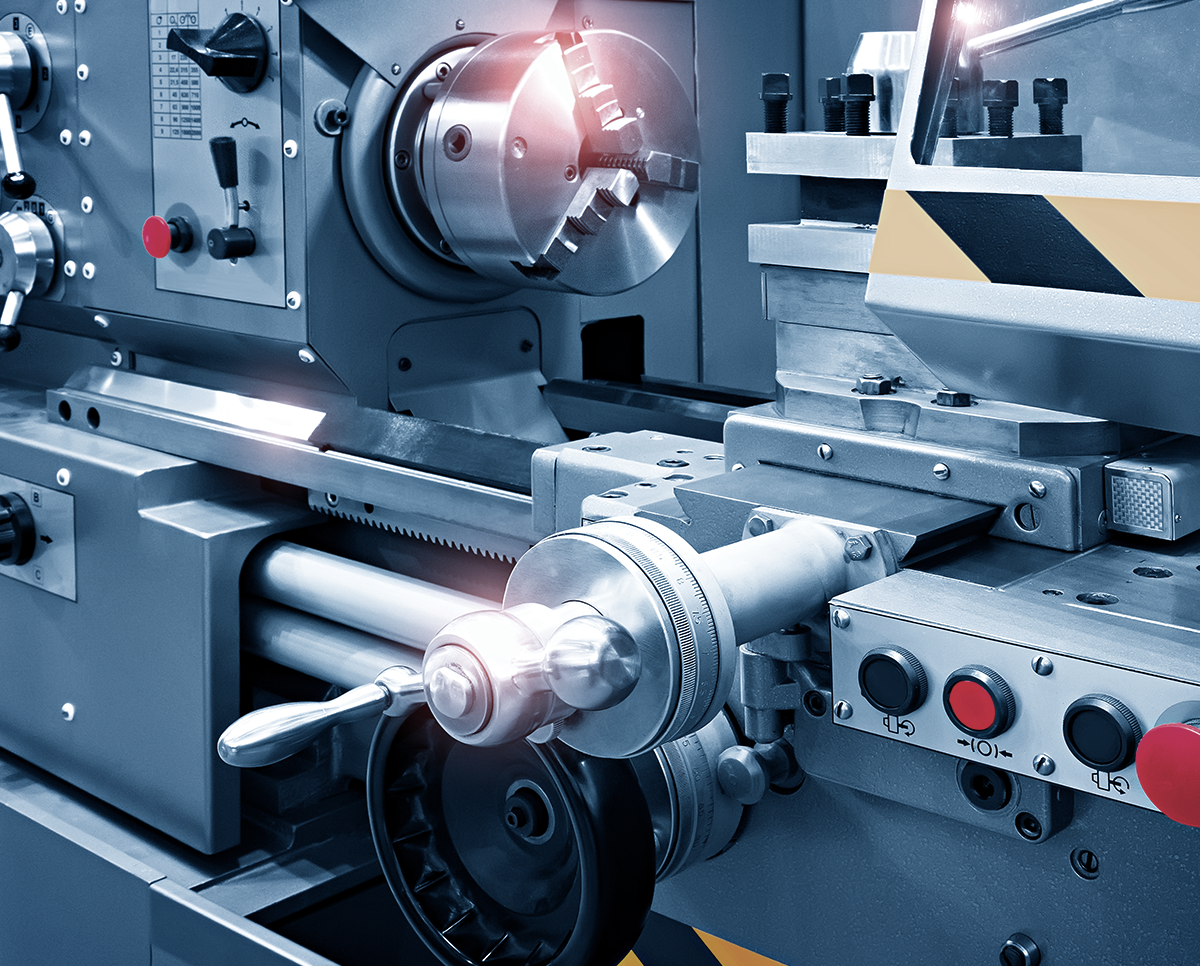

General-purpose, special-purpose or single-purpose machine tools on which chip machining is performed are most often designed for machining metals, wood, and plastics. Their accuracy, performance, efficiency and reliability affect both production costs and product quality, which in turn affects the competitiveness of the finished product.

We produce high-precision AKE bearings mainly for machine tool spindles. See for yourself, whether you are developing a prototype of your customised machine or flexibly producing in small or large series.

With regard to the high precision of bearings in machine tools, AKE bearings meet special technical requirements.

The accuracy of AKE bearings is a key to precision manufacturing operations, where even a small deviation in material machining can affect the quality of the final product. AKE high-precision bearings meet the technical requirements of machine tool manufacturers to achieve very precise spindle geometry.

Most service interventions require the shutdown of important equipment or large-scale technologies. It is therefore preferable to use durable bearings that require only minimal maintenance and achieve a long service life.

Lathes

Cutters

Drilling and boring machines

Grinding machines

Band saws

Machining centres

All bearings from the AKE Skalica production plant are manufactured in accordance with the requirements of the ISO9001 standard.

We manufacture bearings for the machining centres up to the ABEC 7 precision level.

AKE

AKE AKE

AKE AKE

AKE AKE

AKEWe have a team of top experts in the field of structural engineering, material science and high precision manufacturing.

Adaptability of production capacity increase, including product development and production of small series and prototype bearings.

Customer cost savings in compliance with the high quality bearings with ISO9001 certification.

Copyright©2024 IMET-AKE | Privacy Policy | Terms and Conditions | Cookies