The aerospace manufacturing industry is also subject to trends. Their task is to take the functioning of bearings to an even higher level. Which of the manufacturing trends of the aerospace industry are applied in the AKE Skalica plant?

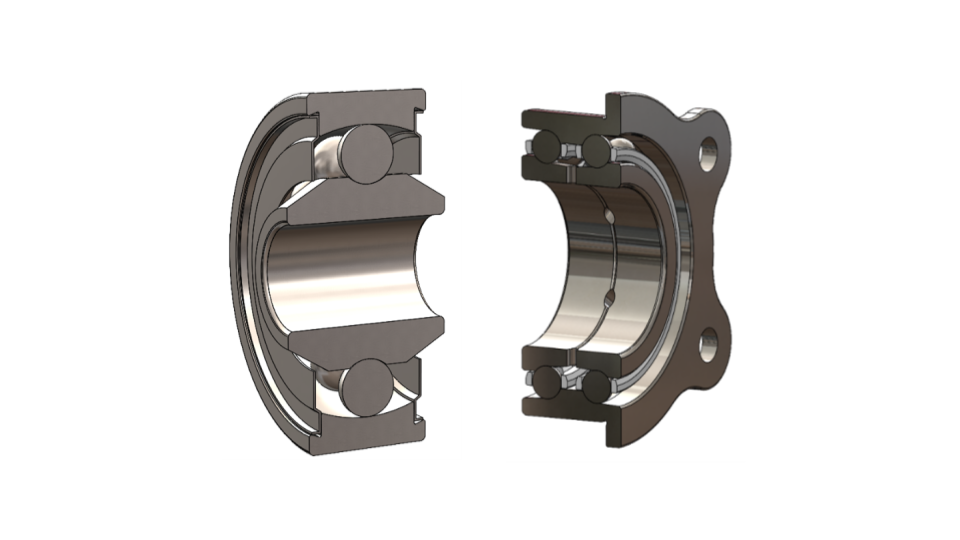

In the past year, we focused our development and production mainly on ball and roller bearings with an outer diameter up to 150 mm. All these bearings are designed and manufactured from HSS M50 material, which is currently one of the manufacturing trends in the aerospace industry.

Our next design development is a design solution for the production of bearings made of HSS M50Nil in combination with Ketron Peek 1000.

Manufacturing trends in the aerospace industry also relate to the way in which surface treatments are applied to improve the properties and, in particular, to extend the lifetime of bearings. They are implemented into the design solutions when designing customized bearings, which we call "customer design".

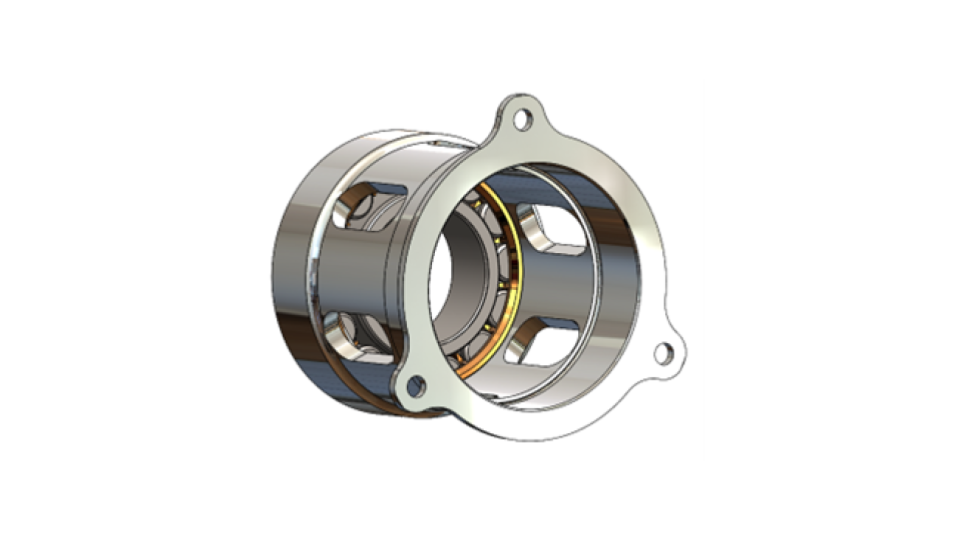

Customer design connects us with the customer's design teams and together we form one development team. One example of such cooperation with a customer is our joint design of the cooling of the working environment with a defined medium, in order to eliminate as much as possible the temperature changes to which the bearing is exposed in operation. This achieves an increase in bearing efficiency to the maximum level.

Current manufacturing trends in the aerospace industry also include simulation of the real operating conditions as accurately as possible in the bearing in the fit. In our external conditions, we are concerned with the adjustment of the forces that will act on the bearing in the bearing fit in real operation. At the same time, by setting these forces, we can ensure that the demanding bearing parameters that are designed in the drawing documentation are adhered to.

All these individual small parts of the development process allow us, in cooperation with the client's development team, to set the parameters of the developed bearing so that it works as efficiently and reliably as possible in the bearing fit for which it is designed.

Another major ongoing challenge that we are currently addressing is the development of bearings for a powerful jet engine with a thrust of 10,000 lbf.

Copyright©2024 IMET-AKE | Privacy Policy | Terms and Conditions | Cookies